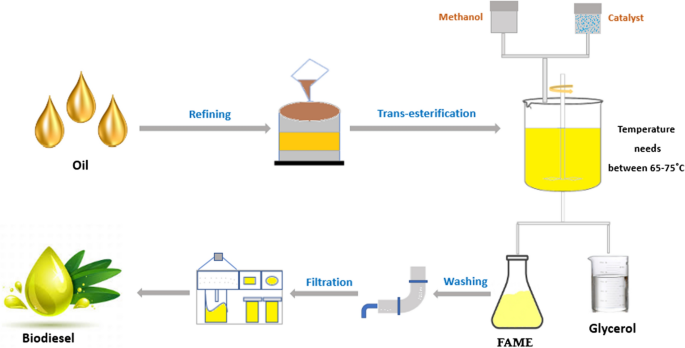

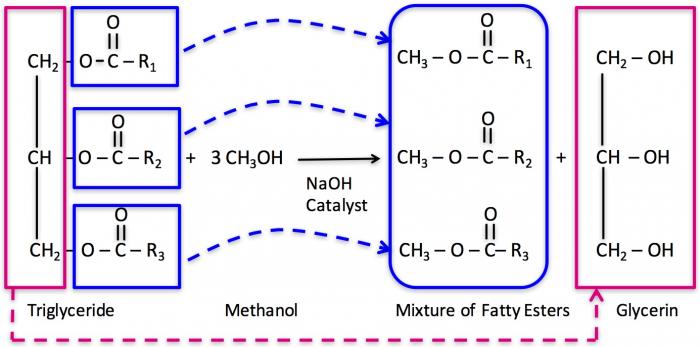

The chemical reaction that converts a vegetable oil or animal fat to biodiesel is called transesterification This is a long name for a simple process of combining a chemical compound called an ester and an. Bioresour Technol 97.

Transesterification Srs Biodieselsrs Biodiesel

Oxo-ligands typically arise via the hydrolysis often accidentally and via ether elimination.

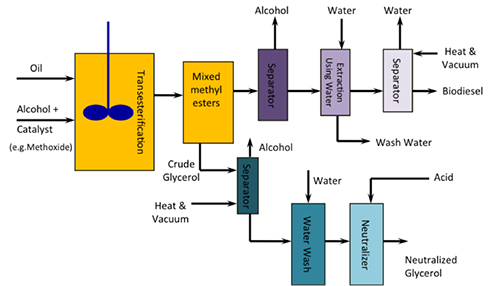

. Schematic of the biodiesel process using transesterification. The second step is transesterification. Production of biodiesel via supercritical methanol transesterification in a tubular reactor.

From there they are mixed methyl esters from which crude glycerol is removed. Biofuel synthesis from algae by transesterification process. The process to make biodiesel involves a chemical reaction.

The reaction can also be accomplished with the help of other enzymes particularly lipases one example is the lipase EC3113. The crude glycerol goes into a separator under heat and a. In the transesterification process.

Thermophysical and transitive properties of supercritical methanol Energ. Naturally occurring antioxidants including antioxidant vitamins eg vitamin C and vitamin E and phytochemical antioxidants. Methanol Separation Schematics Van Gerpen 2014.

As of now transesterification is the most widely used method for biodiesel production. Soon after that chemical approaches for biodiesel production such as pyrolysis and transesterification were introduced to chemically alter natural fats and oils to better suit the fuel industry. There are also solid catalysts that can be used for biodiesel production.

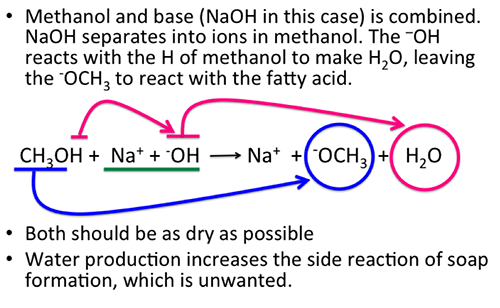

Oil alcohol and a catalyst undergo transesterification. Production of biodiesel is a simple process in two steps Fig. Sodium methoxide for example is commonly used for this purpose a reaction that is used in the production of biodiesel.

Biodiesel Production Purification In the United States there are over 145 large biodiesel production plants. Both transesterification and esterification reactions can be operated either as a batch or continuous process. The conversion of various feedstocks to biodiesel is compared in Fig.

Antioxidants used in food products either natural or synthetic can interact among themselves and result in synergistic additive and antagonistic interactions. A batch process is better suited to smaller plants that produce less than 1 million gallons per year and provide operation flexibility. These plants use a mixture of animal fats soy oils or multiple different feedstocks as the reactant.

This process which. Ghadge SV Raheman H 2006 Process optimization for biodiesel production from mahua Madhuca indica oil using response surface methodology. In an optimization study the effect of enzyme weight.

Algae competes the fellow contestants in the biodiesel synthesis market which gives a insight for future oil demand. The immobilized lipases were then employed in biodiesel production by transesterification of waste cooking oil with methanol. Many metal alkoxide compounds also feature oxo-ligands.

In organic chemistry transesterification is the process of exchanging the organic group R of an ester with the organic group R of an alcoholThese reactions are often catalyzed by the addition of an acid or base catalyst. The first step consists of the extraction of fats or oils from. It has to be noted that catalysts plays a vital role in the biodiesel forming.

Animal or plant tissues. Rong Tsao in Handbook of Antioxidants for Food Preservation 2015. This means that the biodiesel industry is a chemical industry.

The process most commonly used is seen in Figure 4.

Transesterification Srs Biodieselsrs Biodiesel

Enzyme Transesterification Process The Resulting Products Of This Download Scientific Diagram

9 2 The Reaction Of Biodiesel Transesterification Egee 439 Alternative Fuels From Biomass Sources

Scheme 1 Transesterification Process For Biodiesel Production Adapted Download Scientific Diagram

Transesterification Reaction Of Biodiesel Production Download Scientific Diagram

9 2 The Reaction Of Biodiesel Transesterification Egee 439 Alternative Fuels From Biomass Sources

Transesterification Srs Biodieselsrs Biodiesel

C 4 Transesterification Sl Youtube

Transesterification Reaction During Biodiesel Production Using Castor Download Scientific Diagram

Researchers Develop New Continuous Transesterification Process For Biodiesel Production

Role Of Microbial Lipases In Transesterification Process For Biodiesel Production Springerlink

Role Of Microbial Lipases In Transesterification Process For Biodiesel Production Springerlink

Transesterification Reaction In The Biodiesel Production Process Download Scientific Diagram

Reaction Mechanism Of Transesterification Of Plant Oil For Biodiesel Download Scientific Diagram

Widely Used Catalysts In Biodiesel Production A Review Rsc Advances Rsc Publishing Doi 10 1039 D0ra07931f

Transesterification And Its Mechanism Its Application In Dairy Indus

9 2 The Reaction Of Biodiesel Transesterification Egee 439 Alternative Fuels From Biomass Sources

General Reaction Of Enzyme Catalyzed Transesterification Process B Download Scientific Diagram